Inhoudsopgave

Benefits of Using Warm Mix Asphalt (WMA) Additives in Road Construction

Warm mix asphalt (WMA) additives have become increasingly popular in road construction due to their numerous benefits. These additives are designed to lower the production and placement temperatures of asphalt mixtures, resulting in reduced energy consumption and greenhouse gas emissions. In addition to being environmentally friendly, WMA additives offer several advantages that make them a preferred choice for many road construction projects.

| Number | Name |

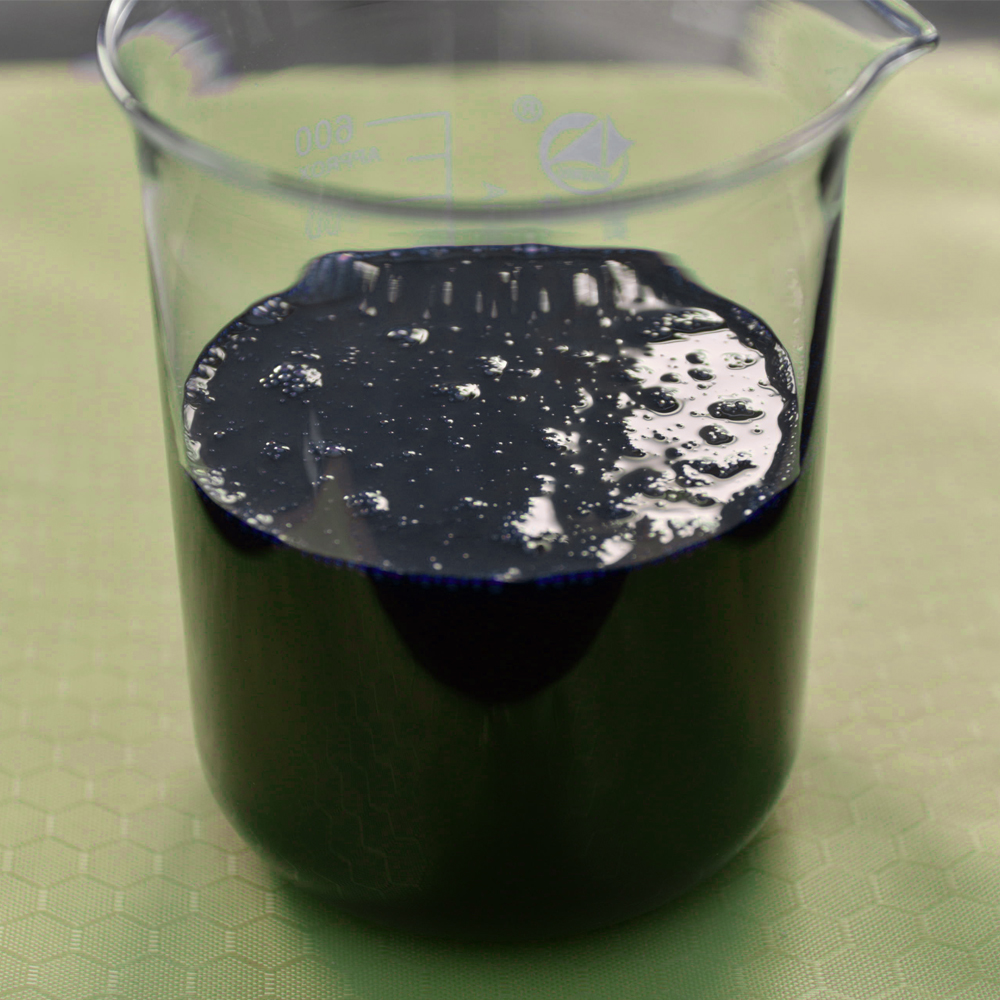

| 1 | warm mix asphalt additives |

One of the key benefits of using WMA additives is improved workability. By lowering the viscosity of the asphalt binder, these additives make it easier to mix and compact the asphalt mixture. This results in better compaction and a more uniform pavement surface, which can help extend the lifespan of the road. In addition, the lower production temperatures associated with WMA additives reduce the risk of thermal cracking, which is a common issue with hot mix asphalt (HMA) pavements.

Another advantage of using WMA additives is the potential for cost savings. Because WMA mixtures can be produced at lower temperatures, less energy is required during the manufacturing process. This can Lead to reduced fuel consumption and lower production costs, making WMA additives a cost-effective option for road construction projects. Additionally, the improved workability of WMA mixtures can result in faster construction times, further reducing labor costs and project timelines.

In addition to cost savings and improved workability, WMA additives offer environmental benefits as well. By reducing the energy consumption and greenhouse gas emissions associated with asphalt production, these additives help minimize the environmental impact of road construction. This can be particularly important for projects in environmentally sensitive areas or those seeking to achieve sustainability goals. Furthermore, the lower production temperatures of WMA mixtures can help reduce the risk of worker exposure to harmful fumes and improve overall air quality on construction sites.

One of the lesser-known benefits of using WMA additives is their ability to enhance pavement performance. Studies have shown that WMA mixtures can exhibit improved rutting resistance, fatigue resistance, and moisture susceptibility compared to traditional HMA mixtures. This can result in longer-lasting pavements that require less maintenance over time, ultimately saving time and money for road agencies and taxpayers. Additionally, the improved performance of WMA mixtures can lead to smoother and quieter road surfaces, enhancing the driving experience for motorists.

Overall, the benefits of using WMA additives in road construction are clear. From improved workability and cost savings to environmental benefits and enhanced pavement performance, WMA additives offer a compelling alternative to traditional HMA mixtures. As the demand for sustainable and cost-effective road construction solutions continues to grow, WMA additives are likely to play an increasingly important role in the industry. By incorporating these additives into their projects, road agencies and contractors can achieve better results for both their bottom line and the Environment.