Inhoudsopgave

Benefits of Using Basalt Fiber in Asphalt Mixtures

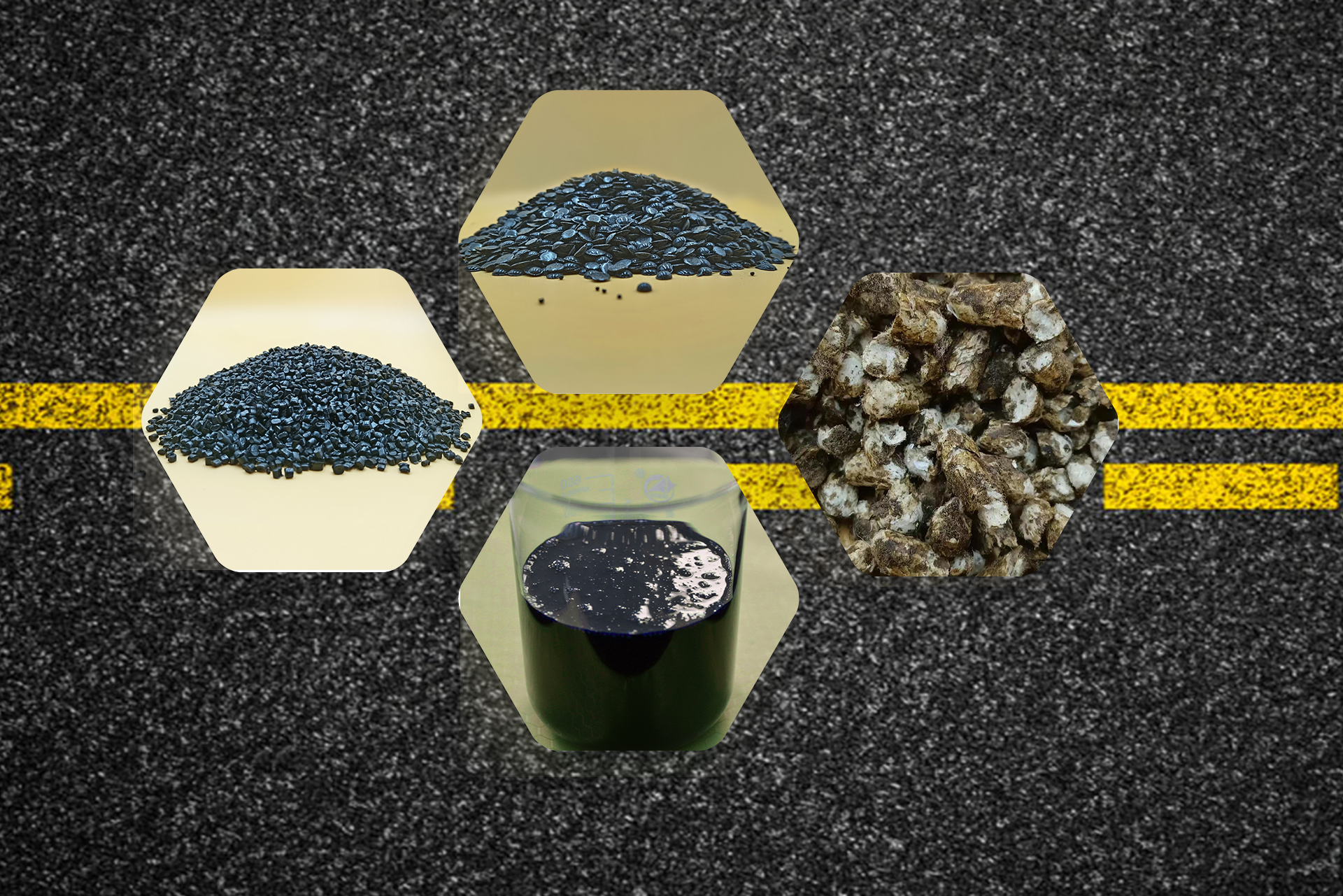

Asphalt is a commonly used material in road construction due to its durability and cost-effectiveness. However, over time, asphalt can deteriorate due to factors such as heavy traffic, extreme weather conditions, and aging. To combat this issue, engineers and researchers have been exploring ways to enhance the durability and longevity of asphalt pavements. One promising solution that has gained traction in recent years is the incorporation of basalt fiber into asphalt mixtures.

Basalt fiber is a natural material derived from volcanic rock, which is known for its high tensile strength and resistance to corrosion. When added to asphalt mixtures, basalt fiber can significantly improve the performance of the pavement by enhancing its strength, flexibility, and resistance to cracking. This, in turn, leads to a longer service life for the pavement and reduced maintenance costs for road authorities.

One of the key benefits of using basalt fiber in asphalt mixtures is its ability to increase the tensile strength of the pavement. Tensile strength is crucial for withstanding the tensile stresses that occur during the loading and unloading of vehicles on the pavement. By reinforcing the asphalt mixture with basalt fiber, engineers can effectively increase the pavement’s ability to resist cracking and rutting, resulting in a more durable and long-lasting road surface.

In addition to improving tensile strength, basalt fiber also enhances the flexibility of the asphalt pavement. Flexibility is essential for accommodating the thermal expansion and contraction of the pavement due to changes in temperature. By adding basalt fiber to the asphalt mixture, engineers can create a more flexible pavement that can better withstand temperature fluctuations without cracking or deforming. This increased flexibility not only improves the overall performance of the pavement but also reduces the likelihood of premature failure.

Furthermore, basalt fiber is highly resistant to corrosion, making it an ideal material for use in asphalt mixtures. Corrosion can occur due to exposure to moisture, Chemicals, and other environmental factors, leading to the deterioration of the pavement over time. By incorporating basalt fiber into the asphalt mixture, engineers can create a corrosion-resistant pavement that is better able to withstand the harsh conditions of the road Environment. This increased resistance to corrosion helps to prolong the service life of the pavement and reduce the need for frequent repairs and maintenance.

| No. | Commodity Name |

| 1 | Industrial chopped basalt fibers |

Overall, the use of basalt fiber in asphalt mixtures offers a range of benefits that can significantly improve the durability and longevity of the pavement. By enhancing tensile strength, flexibility, and resistance to corrosion, basalt fiber helps to create a more robust and long-lasting road surface that can withstand the rigors of heavy traffic and harsh weather conditions. As road authorities continue to seek sustainable and cost-effective solutions for road construction, the incorporation of basalt fiber into asphalt mixtures is likely to become an increasingly popular choice for enhancing the performance of asphalt pavements.