Table of Contents

Benefits of Incorporating Wood Pulp Fibers in Bitumen

Bitumen, a sticky, black, and highly viscous liquid or semi-solid form of petroleum, is a key component in the construction of roads, highways, and other infrastructure projects. It is commonly used as a binding agent in asphalt mixtures to provide durability and strength to the pavement. In recent years, there has been a growing interest in incorporating wood pulp fibers into bitumen to enhance its performance and sustainability.

One of the main benefits of using wood pulp fibers in bitumen is their ability to improve the overall strength and durability of the asphalt mixture. Wood pulp fibers are known for their high tensile strength and flexibility, which can help to reduce cracking and rutting in the pavement. By adding wood pulp fibers to bitumen, engineers can create a more resilient and long-lasting road surface that can withstand heavy traffic loads and harsh weather conditions.

In addition to enhancing the mechanical properties of asphalt, wood pulp fibers can also improve the workability and compaction of the mixture during construction. The fibers act as a stabilizing agent, helping to distribute the bitumen evenly throughout the aggregate and ensuring a more uniform and consistent pavement surface. This can Lead to a smoother ride for drivers and reduce the need for costly maintenance and repairs in the future.

Furthermore, incorporating wood pulp fibers in bitumen can have environmental benefits as well. Wood pulp fibers are a renewable and biodegradable material, making them a more sustainable alternative to traditional additives used in asphalt mixtures. By using wood pulp fibers, engineers can reduce their reliance on non-renewable resources and decrease the carbon footprint of road construction projects. This aligns with the growing trend towards green building practices and sustainable infrastructure development.

Another advantage of using wood pulp fibers in bitumen is their ability to improve the thermal and acoustic properties of the pavement. The fibers act as an insulating layer, helping to regulate the temperature of the asphalt and reduce noise Levels from traffic. This can create a more comfortable and safer driving experience for motorists, as well as reduce the overall environmental impact of roadways on surrounding communities.

Overall, the benefits of incorporating wood pulp fibers in bitumen are clear. From enhancing the strength and durability of the pavement to improving workability and compaction during construction, wood pulp fibers offer a range of advantages for engineers and contractors. Additionally, their renewable and biodegradable nature makes them a more sustainable choice for road construction projects, aligning with the growing demand for environmentally friendly building materials.

As the construction industry continues to prioritize sustainability and innovation, the use of wood pulp fibers in bitumen is likely to become more widespread. By harnessing the unique properties of this natural material, engineers can create stronger, more durable, and more environmentally friendly roadways that benefit both drivers and the planet.

Sustainable Practices in Asphalt Production: Utilizing Wood Pulp Fibers

Asphalt is a commonly used material in road construction due to its durability and ability to withstand heavy traffic. However, the production of asphalt can have negative environmental impacts, such as the emission of greenhouse gases and the depletion of natural resources. In recent years, there has been a growing interest in finding sustainable alternatives to traditional asphalt production methods. One such alternative is the use of wood pulp fibers in asphalt.

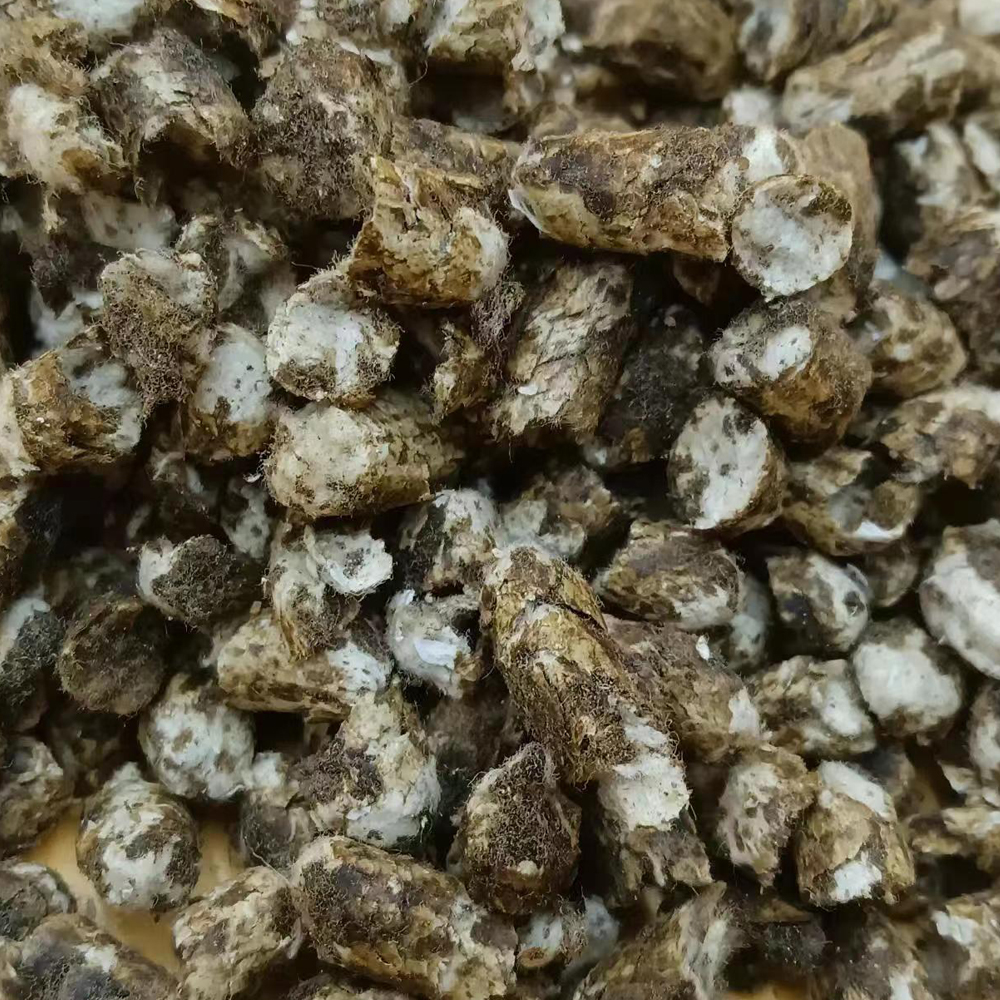

Wood pulp fibers are a byproduct of the paper-making process and are typically discarded as waste. However, researchers have found that these fibers can be used as a sustainable additive in asphalt production. When mixed with bitumen, the main binding agent in asphalt, wood pulp fibers can improve the overall performance of the material.

One of the key benefits of using wood pulp fibers in asphalt is their ability to increase the flexibility and durability of the material. This can help to reduce cracking and rutting on roads, leading to a longer lifespan for the pavement. Additionally, wood pulp fibers can improve the overall strength of the asphalt, making it more resistant to wear and tear from heavy traffic.

Another advantage of using wood pulp fibers in asphalt is their ability to absorb and retain moisture. This can help to prevent water from seeping into the pavement and causing damage over time. By reducing the amount of water that penetrates the asphalt, wood pulp fibers can help to extend the life of the road and reduce the need for costly repairs.

In addition to their performance benefits, wood pulp fibers are also a sustainable alternative to traditional additives used in asphalt production. Because they are a byproduct of the paper-making process, wood pulp fibers are readily available and do not require the extraction of new resources. This can help to reduce the environmental impact of asphalt production and promote a more sustainable approach to road construction.

Furthermore, the use of wood pulp fibers in asphalt can help to reduce the carbon footprint of the material. By incorporating a renewable and biodegradable additive into the asphalt mix, producers can lower the overall emissions associated with the production and transportation of the material. This can help to mitigate the environmental impact of road construction and contribute to a more sustainable infrastructure system.

Overall, the use of wood pulp fibers in asphalt offers a promising solution for improving the sustainability of road construction. By enhancing the performance of the material, reducing its environmental impact, and promoting a more sustainable approach to production, wood pulp fibers can help to create more durable and eco-friendly roads. As researchers continue to explore the potential of this innovative additive, we can expect to see more widespread adoption of wood pulp fibers in asphalt production in the years to come.

| Serial Number | Name |

| 1 | Lignin Fibers |