Table of Contents

Advantages of Using High Carbon Steel in Eco-Friendly Construction Projects

High carbon steel is a popular material used in various construction projects due to its strength and durability. However, there has been some debate about whether high carbon steel is environmentally friendly. In this article, we will explore the advantages of using high carbon steel in eco-friendly construction projects.

One of the main advantages of using high carbon steel in construction is its longevity. High carbon steel is known for its ability to withstand wear and tear, making it a durable material for building structures that will last for many years. This longevity reduces the need for frequent repairs or replacements, which can help reduce the overall environmental impact of a construction project.

Additionally, high carbon steel is a recyclable material. When a building made with high carbon steel reaches the end of its life cycle, the steel can be recycled and used to create new products. This reduces the amount of waste that ends up in landfills and helps conserve natural resources. By using high carbon steel in construction, builders can contribute to a more sustainable and eco-friendly building industry.

Another advantage of using high carbon steel in construction is its energy efficiency. High carbon steel has a high strength-to-weight ratio, which means that less material is needed to achieve the same level of structural integrity compared to other materials. This can result in lighter buildings that require less energy to heat and cool, reducing the overall carbon footprint of a construction project.

Furthermore, high carbon steel is a versatile material that can be used in a wide range of construction applications. From beams and columns to reinforcement bars and roofing materials, high carbon steel can be tailored to meet the specific needs of a project. This versatility allows builders to create innovative and sustainable designs that maximize the use of resources and minimize waste.

In addition to its environmental benefits, high carbon steel also offers economic advantages for construction projects. While the initial cost of high carbon steel may be higher than other materials, the long-term savings from reduced maintenance and energy costs can offset this expense. Additionally, the recyclability of high carbon steel can provide a source of revenue for builders who choose to sell the material after a building is demolished.

Overall, high carbon steel is a sustainable and eco-friendly material that offers numerous advantages for construction projects. Its durability, recyclability, energy efficiency, and versatility make it an ideal choice for builders who are committed to reducing their environmental impact. By using high carbon steel in construction, builders can create structures that are not only strong and resilient but also environmentally responsible.

The Environmental Impact of Continuous Coil Mattresses

Continuous coil mattresses are a popular choice for many consumers due to their affordability and durability. However, there has been growing concern about the environmental impact of these mattresses, particularly when it comes to the materials used in their construction. One material that is commonly used in continuous coil mattresses is high carbon steel. But is high carbon steel environmentally friendly?

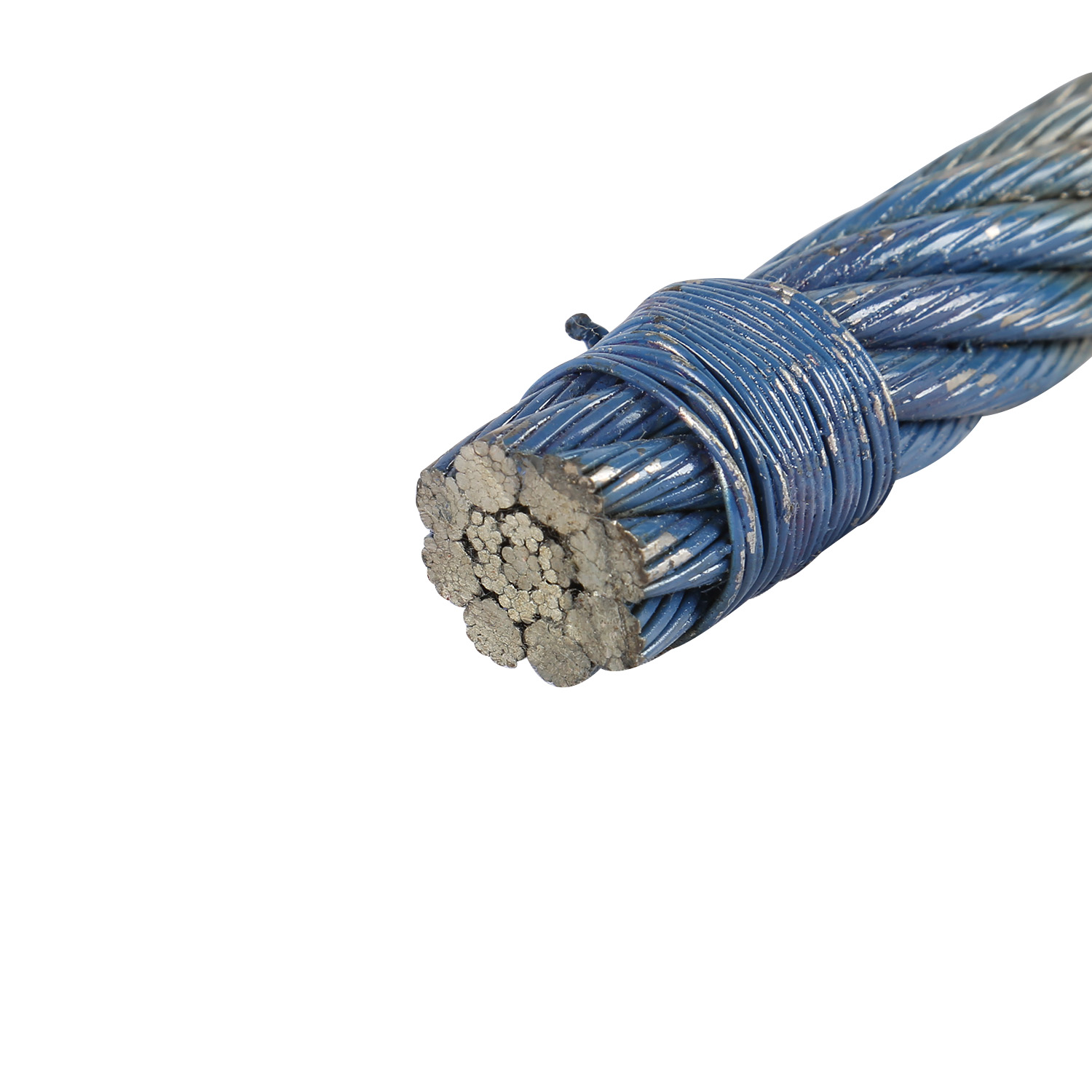

High carbon steel is a type of steel that contains a higher percentage of carbon than other types of steel. This makes it stronger and more durable, which is why it is often used in the construction of continuous coil mattresses. However, the production of high carbon steel is not without its environmental consequences.

The process of manufacturing high carbon steel involves the use of large amounts of energy and resources. This can Lead to increased carbon emissions and other pollutants being released into the atmosphere. Additionally, the mining of the raw materials needed to make high carbon steel can have a negative impact on the Environment, as it can lead to deforestation, habitat destruction, and water pollution.

Despite these environmental concerns, high carbon steel does have some advantages when it comes to sustainability. For one, it is a highly recyclable material. This means that at the end of its life cycle, high carbon steel can be melted Down and reused to make new products, reducing the need for new raw materials to be mined.

Furthermore, continuous coil mattresses made with high carbon steel tend to be more durable than other types of mattresses. This means that they have a longer lifespan and do not need to be replaced as frequently, reducing the overall environmental impact of mattress production.

However, it is important to consider the entire life cycle of a product when evaluating its environmental impact. While high carbon steel may be recyclable and durable, the energy and resources required to produce it in the first place cannot be overlooked. Additionally, the transportation of raw materials and finished products can also contribute to carbon emissions and other pollutants.

In conclusion, while high carbon steel is a common material used in the construction of continuous coil mattresses, its environmental impact should not be ignored. The production of high carbon steel can have negative consequences for the environment, including increased carbon emissions and habitat destruction. However, its recyclability and durability do offer some sustainability benefits.

As consumers, it is important to consider the environmental impact of the products we purchase, including the materials used in their construction. While high carbon steel may have its drawbacks, there are also ways to mitigate its impact, such as Recycling and choosing products with longer lifespans. Ultimately, the decision of whether high carbon steel is environmentally friendly will depend on a variety of factors, including individual priorities and values.

Sustainable Practices in High Carbon Steel Production for Mattress Manufacturing

High carbon steel is a popular material used in the manufacturing of mattresses, particularly in the construction of continuous coil systems. This type of steel is known for its durability and strength, making it an ideal choice for providing support and stability in mattresses. However, there has been growing concern about the environmental impact of high carbon steel production and its use in mattress manufacturing.

One of the main issues with high carbon steel is its high carbon footprint. The production of high carbon steel involves the extraction of Iron ore, which requires a significant amount of energy and resources. Additionally, the process of converting iron ore into steel involves the use of Coal and other fossil fuels, which release greenhouse gases into the atmosphere. This contributes to climate change and air pollution, making high carbon steel production a major contributor to environmental degradation.

Despite these environmental concerns, there are sustainable practices that can be implemented in high carbon steel production to minimize its impact on the environment. One such practice is the use of recycled steel. By using recycled steel instead of virgin steel, manufacturers can reduce the demand for new steel production, which in turn reduces the energy and resources required for steel manufacturing. This helps to lower the carbon footprint of high carbon steel production and promotes a more sustainable approach to mattress manufacturing.

Another sustainable practice in high carbon steel production is the use of Renewable Energy sources. By powering steel production facilities with renewable energy sources such as solar or wind power, manufacturers can reduce their reliance on fossil fuels and decrease their carbon emissions. This not only helps to mitigate the environmental impact of high carbon steel production but also contributes to the transition towards a more sustainable energy system.

In addition to using recycled steel and renewable energy sources, manufacturers can also implement energy-efficient technologies and processes in high carbon steel production. By optimizing energy use and reducing waste in steel manufacturing, manufacturers can further reduce the environmental impact of high carbon steel production. This can include investing in energy-efficient equipment, implementing recycling programs, and adopting sustainable practices throughout the production process.

Overall, while high carbon steel may not be inherently environmentally friendly, there are sustainable practices that can be implemented to minimize its impact on the environment. By using recycled steel, renewable energy sources, and energy-efficient technologies, manufacturers can reduce the carbon footprint of high carbon steel production and promote a more sustainable approach to mattress manufacturing. As consumer demand for eco-friendly products continues to grow, it is important for manufacturers to prioritize sustainability in high carbon steel production and contribute to a more environmentally conscious industry.