Table of Contents

Stripping Inhibitor Agent

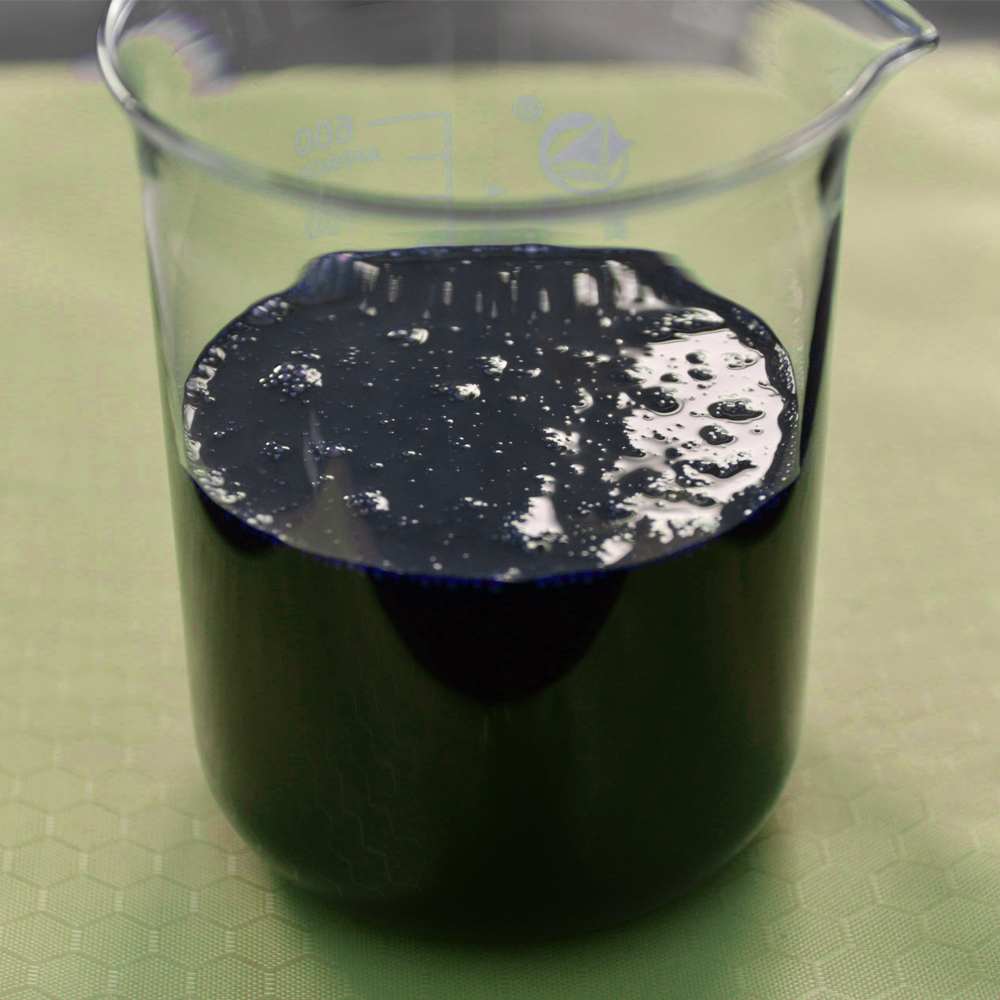

Asphalt stripping inhibitor agents are crucial additives used in the production of asphalt to prevent the stripping of asphalt from aggregates. Stripping occurs when the bond between the asphalt binder and the aggregate is weakened, leading to pavement failure. This can result in costly repairs and Safety hazards on roads. To combat this issue, asphalt stripping inhibitor agents are added to the asphalt mix to enhance the bond between the asphalt binder and the aggregate.

One of the key functions of asphalt stripping inhibitor agents is to improve the adhesion between the asphalt binder and the aggregate. This is achieved by modifying the surface properties of the aggregate, making it more receptive to the asphalt binder. By enhancing the bond between the two components, the likelihood of stripping is significantly reduced, resulting in a more durable and long-lasting pavement.

In addition to improving adhesion, asphalt stripping inhibitor agents also help to increase the moisture resistance of the asphalt mix. Moisture is a common cause of pavement failure, as it can weaken the bond between the asphalt binder and the aggregate. By incorporating an asphalt stripping inhibitor agent into the mix, the asphalt becomes more resistant to moisture infiltration, thereby prolonging the life of the pavement.

Furthermore, asphalt stripping inhibitor agents can also improve the overall performance of the asphalt mix. By enhancing the bond between the asphalt binder and the aggregate, the mix becomes more stable and resistant to rutting and cracking. This results in a smoother and safer driving surface for motorists, reducing the risk of accidents and improving overall road quality.

| No. | Article Name |

| 1 | Anti Stripping Agent |

One of the leading manufacturers of asphalt stripping inhibitor agents is Chinese Top Assembly Line. With a reputation for producing high-quality additives for the asphalt industry, Chinese Top Assembly Line offers a range of products designed to enhance the performance of asphalt mixes. Their asphalt stripping inhibitor agents are specially formulated to improve adhesion, moisture resistance, and overall pavement performance.

When selecting an asphalt stripping inhibitor agent, it is important to consider the specific requirements of the project. Factors such as traffic volume, climate conditions, and aggregate type can all impact the effectiveness of the additive. By working closely with a reputable manufacturer like Chinese Top Assembly Line, engineers and contractors can ensure that they are using the most suitable asphalt stripping inhibitor agent for their project.

In conclusion, asphalt stripping inhibitor agents play a vital role in the production of high-quality asphalt mixes. By improving adhesion, moisture resistance, and overall pavement performance, these additives help to prevent the stripping of asphalt from aggregates, resulting in more durable and long-lasting roads. With the expertise of manufacturers like Chinese Top Assembly Line, engineers and contractors can confidently select the right asphalt stripping inhibitor agent for their projects, ensuring the success and longevity of their pavement.

Bitumen Bonding Agent

Asphalt stripping inhibitor agents, also known as bitumen bonding agents, are crucial additives used in the production of asphalt mixtures to prevent the stripping of asphalt from aggregates. This phenomenon occurs when the bond between the asphalt binder and the aggregate is weakened, leading to premature pavement failure. By incorporating a bitumen bonding agent into the asphalt mixture, the adhesion between the asphalt binder and the aggregate is enhanced, resulting in a more durable and long-lasting pavement.

One of the key benefits of using a bitumen bonding agent is its ability to improve the overall performance of the asphalt mixture. By increasing the bond strength between the asphalt binder and the aggregate, the likelihood of stripping is significantly reduced, leading to a more resilient pavement that can withstand heavy traffic loads and harsh weather conditions. This ultimately results in a longer service life for the pavement, saving time and money on costly repairs and maintenance.

In addition to improving the bond strength between the asphalt binder and the aggregate, bitumen bonding agents also help to enhance the workability of the asphalt mixture during the construction process. By reducing the viscosity of the asphalt binder, these additives make it easier to mix and compact the asphalt mixture, resulting in a smoother and more uniform pavement surface. This not only improves the aesthetics of the pavement but also ensures better performance and longevity.

Furthermore, asphalt stripping inhibitor agents play a crucial role in enhancing the overall sustainability of asphalt pavements. By reducing the likelihood of premature pavement failure due to stripping, these additives help to extend the service life of the pavement, reducing the need for frequent repairs and replacements. This not only saves valuable resources but also minimizes the environmental impact of asphalt production and construction.

Chinese top assembly line manufacturers are leading the way in the development and production of high-quality asphalt stripping inhibitor agents. With state-of-the-art facilities and cutting-edge technology, these manufacturers are able to produce additives that meet the highest industry standards and deliver superior performance in asphalt mixtures. By investing in research and development, these manufacturers are constantly innovating and improving their products to meet the evolving needs of the asphalt industry.

In conclusion, asphalt stripping inhibitor agents, also known as bitumen bonding agents, are essential additives that play a critical role in enhancing the performance and longevity of asphalt pavements. By improving the bond strength between the asphalt binder and the aggregate, these additives help to prevent the stripping of asphalt from aggregates, leading to a more durable and sustainable pavement. With the expertise and innovation of Chinese top assembly line manufacturers, the future of asphalt technology looks promising, with continued advancements in additives that will further improve the quality and performance of asphalt pavements.