Table of Contents

Benefits of Using Float Collar and Float Shoe in Cementing Operations

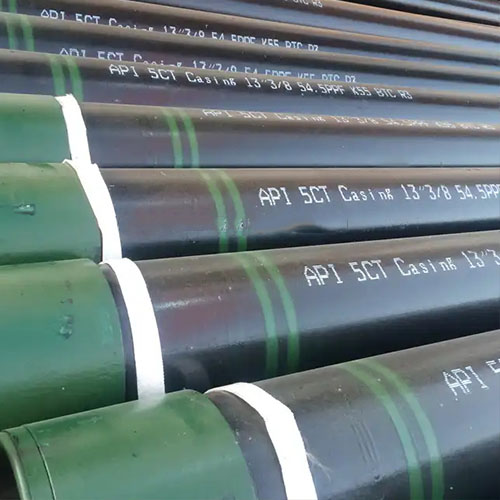

Cementing operations are a critical component of well construction in the oil and gas industry. Proper cementing ensures the integrity of the wellbore, prevents fluid migration, and provides zonal isolation. One key aspect of cementing operations is the use of float collar and float shoe check Valves, specifically the non-rotating type. These tools play a crucial role in the success of cementing operations by facilitating the placement of Cement in the annulus between the casing and the wellbore.

Float collars and float shoes are essential components of the casing string that help to control the flow of cement during the cementing process. The float collar is located at the bottom of the casing string, while the float shoe is located at the top. Both tools are equipped with check valves that allow cement to flow Down the casing string but prevent it from flowing back up. This ensures that the cement is properly placed in the annulus and prevents any potential issues such as channeling or incomplete cement coverage.

One of the key benefits of using float collar and float shoe check valves in cementing operations is their ability to prevent fluid migration. Fluid migration occurs when fluids from one zone in the wellbore migrate into another zone, compromising the integrity of the well. By using float collar and float shoe check valves, operators can ensure that the cement is properly placed and that fluid migration is minimized.

Another benefit of using float collar and float shoe check valves is their ability to provide zonal isolation. Zonal isolation is crucial in well construction as it helps to prevent communication between different zones in the wellbore. By using float collar and float shoe check valves, operators can ensure that each zone is properly isolated and that there is no communication between them. This is essential for maintaining well integrity and preventing any potential issues such as crossflow or gas migration.

The non-rotating type of float collar and float shoe check valves offer additional benefits compared to rotating types. Non-rotating float collars and float shoes are designed to prevent rotation during the cementing process, ensuring that the check valves remain in the correct position. This helps to prevent any potential issues such as valve failure or improper cement placement. Additionally, non-rotating float collars and float shoes are more reliable and require less maintenance compared to rotating types.

In conclusion, float collar and float shoe check valves are essential tools in cementing operations that offer a range of benefits. These tools help to prevent fluid migration, provide zonal isolation, and ensure proper cement placement in the annulus. The non-rotating type of float collar and float shoe check valves offer additional advantages in terms of reliability and maintenance. By using float collar and float shoe check valves in cementing operations, operators can ensure the success of their well construction projects and maintain the integrity of the wellbore.

Advantages of Non-Rotating Type Check Valve in Cementing Tools

Cementing tools play a crucial role in the oil and gas industry, ensuring the integrity of wellbore construction and preventing any potential leaks or blowouts. Among the various components of cementing tools, the float collar and float shoe check valve are essential for a successful cementing operation. In this article, we will focus on the advantages of the non-rotating type check valve in cementing tools.

The float collar and float shoe are key components of the casing string, serving as a guide for the casing during the cementing process. The float collar is placed at the bottom of the casing string, while the float shoe is installed at the top. These components help to prevent the backflow of cement slurry during the cementing operation, ensuring that the cement is properly placed and bonded to the wellbore.

One of the key advantages of the non-rotating type check valve in cementing tools is its ability to prevent rotation of the casing string during the cementing process. Rotating the casing string can Lead to uneven distribution of cement slurry, resulting in poor zonal isolation and potential leaks. The non-rotating type check valve ensures that the casing string remains stationary, allowing for a more uniform placement of cement around the wellbore.

Another advantage of the non-rotating type check valve is its ability to withstand high pressure and temperature conditions. During the cementing operation, the casing string is subjected to extreme pressure and temperature variations. The non-rotating type check valve is designed to withstand these harsh conditions, ensuring that it remains operational throughout the cementing process.

Furthermore, the non-rotating type check valve is easy to install and maintain, reducing downtime and increasing efficiency during the cementing operation. The simple design of the non-rotating type check valve allows for quick and easy installation, saving time and resources. Additionally, the valve is designed for minimal maintenance, reducing the need for frequent repairs or replacements.

In conclusion, the non-rotating type check valve offers several advantages in cementing tools, including preventing rotation of the casing string, withstanding high pressure and temperature conditions, and easy installation and maintenance. These advantages make the non-rotating type check valve an essential component of cementing tools, ensuring the success of wellbore construction and cementing operations in the oil and gas industry. By choosing the non-rotating type check valve for your cementing tools, you can improve efficiency, reduce downtime, and enhance the integrity of your wellbore construction.

https://www.youtube.com/watch?v=yRqVb0LdTVk